Project Detail

Warning: Trying to access array offset on false in /home/hagorbuk/ge-hydro.work/wp-content/plugins/wp-google-map-gold/modules/shortcode/views/put-wpgmp.php on line 1799

Assab Regional Hospital Construction

In response to the lack of adequate healthcare facilities in the Assab region, the Southern Red Sea Regional Eritrean Defense Force (EDF) initiated the construction of a referral hospital in January 2000. The project aimed to provide essential healthcare services for the region and was located on the outskirts of the city of Assab.

Enterprise

Southern Red Sea Eritrean Defense Force (EDF) Construction Department, Assab, Eritrea

Construction Period

June 2000 – Early 2006

Project Details

The project involved the construction of a ground-plus-one complex, including an outpatient department (OPD) and a 200-bed healthcare facility. In addition, several auxiliary service buildings were constructed to support the main hospital.

The hospital was designed to accommodate specialized healthcare sectors, including:

- Obstetrics and Gynecology

- Orthopedics

- Surgical Theater

- Internal Medicine

- Dentistry (Odontology)

- Pediatrics

According to the design documents, the total surface area of the construction site was approximately 124 m².

Figure 1 provides a bird’s-eye view of the Assab hospital facility, illustrating the scope and layout of the project.

Figure 1 Building complex of Assab referral hospital.

Foundation and Ground Conditions

The region surrounding Assab, being a wasteland adjacent to the Red Sea, presented challenging ground conditions characterized by a high salt content. To mitigate the detrimental effects of salt on the building’s structural integrity, all footings were constructed using sulfate-resisting cement (SRC).

In Assab, it is common to see structures deteriorate due to salt intrusion. Salt rises through capillaries in the soil, damaging walls and columns over time. This eventually leads to the corrosion of reinforcement bars, compromising the building’s load-bearing capacity. To prevent such issues, the use of sulfate-resisting cement was critical for the foundation.

Sulfate-Resisting Cement

Sulfate-resisting cement not only reduces heat generation during curing but also offers excellent resistance to sulfate, chloride, and saltwater, making it ideal for construction in such conditions.

Layout

The layout process began with the transfer of key points from the design to the ground using surveying instruments, including a theodolite and a leveling instrument. Once the points were marked, batter boards and construction lines were established to guide the excavation process. The foundation excavation was carried out using a mechanical excavator to remove the dirt efficiently.

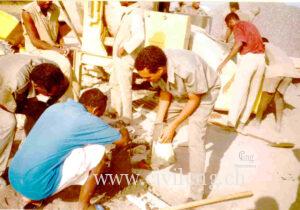

Lean Concreting

A 5 cm layer of lean concrete was poured before placing the foundation formwork. This layer served as a base for the formwork and ensured a stable, level surface for the foundation.

Figure 2 depicts the lean concreting process at the Assab Hospital construction site.

Figure 2 Lean concreting at Assab Hospital construction site

Foundation Placement

Due to the rocky and robust geological formation of the site, the excavation depth was limited to approximately 1.5 to 2 meters. The foundation type employed was a spread footing foundation, with each footing measuring approximately 120 cm × 85 cm and a depth of 45 cm.

The girder beams and all columns were cast in situ, ensuring structural integrity and adaptability to site-specific conditions.

Figures 3a, 3b, and 3c illustrate the placement of foundations and columns at the Assab Hospital construction site.

Figure 3a Constructing the foundation and columns of the Assab referral hospital.

Figure 3b Single spread foot foundation utilized at Assab hospital.

Figure 3c Foundation formwork placement.

Concrete Mixing Ratio

The standard mortar mix used for the project was B25. The same mix ratio was applied for the foundation, beams, and columns, consisting of a cement: sand: gravel ratio of 1:2:4.

Figure 4 shows the concrete mixing machinery used during the construction of the Assab hospital.

Figure 4 Mobile concrete mixer utilized at Assab hospital

Slump Test

A standard concrete mixing procedure was followed during construction, and the concrete paste was inspected using a simple yet effective method known as the slump test. This technique is crucial for assessing the consistency of the concrete mix to prevent the adverse effects of excess water.

Excess water in the concrete mix can compromise the structure by leaving cracks as the water evaporates. These cracks can expose the reinforcement bars to corrosion, ultimately leading to premature structural failure. Therefore, ensuring the correct consistency of the concrete mix is essential to maintain the integrity and durability of the building.

Figure 5 illustrates the slump test procedure used at the Assab Hospital construction site.

Figure 5 Slump test

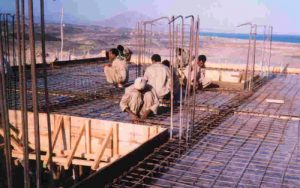

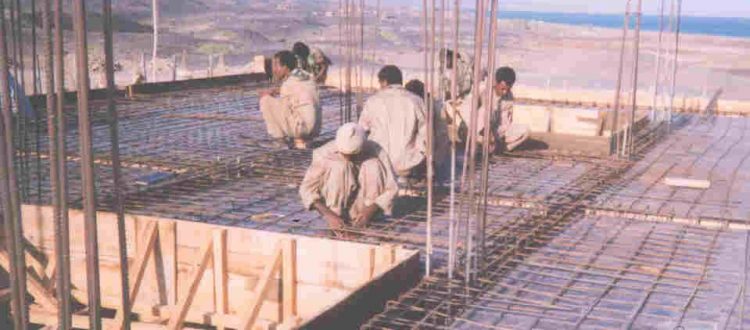

Figures 6a and 6b show the structural framework of the OPD building.

Figure 6a Outpatient department construction in progress

Figure 6b First-floor reinforcement placement

Floors and Roofs

The first floor consists of a 15 cm thick reinforced concrete slab. A terrace is located at the left corner of the building, providing an outdoor lounging area.

The roof is also constructed with a 15 cm thick reinforced concrete slab, topped by a 50 cm high parapet wall surrounding the rooftop for added safety and functionality.

Figure 7 depicts the completed OPD building, showcasing its structural details.

Figure 7 Assab referral hospital completed OPD building