Project Detail

Warning: Trying to access array offset on false in /home/hagorbuk/ge-hydro.work/wp-content/plugins/wp-google-map-gold/modules/shortcode/views/put-wpgmp.php on line 1799

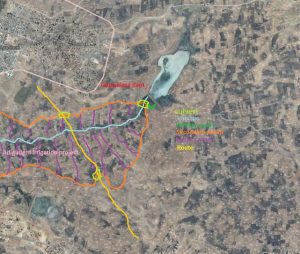

Figure 1 Adigudem surface irrigation project (Gumselasa dam), Tigray, Ethiopia.

Enterprise

The project was managed by Sustainable Agriculture and Environmental Rehabilitation in Tigray Region (SAERT), a semi-governmental institute headquartered in Mekele, located in the northern region of Ethiopia.

Period of Construction

February 1996 – November 1996

Project Details

Based on data from the land survey, the irrigated farmland covered an area of 136 hectares. The designed method of irrigation was surface irrigation, comprising:

- Primary (Principal) Canal: Trapezoidal in shape.

- Secondary Canals: Trapezoidal, located along the extreme left and right boundaries of the farmland.

- Tertiary Canals: Trapezoidal, running perpendicular from the secondary canals into the fields, distributing water into side furrows (see Figure 1).

A natural waterway existing in the middle of the farmland was utilized as a drainage channel for excess water, ensuring proper water management and preventing waterlogging.

Drop Structures

The canals included approximately 400 concrete drop structures (canal falls) with the following dimensions:

- Height: 1–1.7 meters

- Width: 90–120 centimeters

- Thickness: 30 centimeters

The downstream and upstream sides of the drop structures were equipped with simple stone aprons (constructed without mortar) to minimize erosion. Additionally, two large drop structures were installed with stilling basins on the downstream side and concrete aprons on the upstream side for enhanced water flow control.

Figures

- Figure 1: Illustrates the design layout of the Adigudem Surface Irrigation Project, showing the alignment of the canals and the natural drainage system.

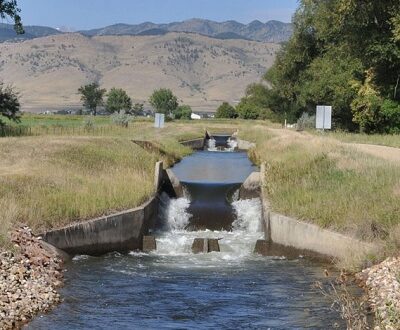

- Figure 2: Depicts a drop structure similar to those constructed at the Adigudem site. While the image is not taken directly from the project, it provides a visual representation of the structures built for the irrigation system.

Culverts

Three culverts were constructed as part of the irrigation infrastructure:

- Two culverts were installed along the route to provide passage for tractors between different sections of the farm.

- The third culvert was used to connect the primary canal to the right-side secondary canal, ensuring efficient water distribution.

Canal Excavation

The canals were excavated manually by local communities with minimal assistance from machinery, showcasing the significant contribution of community labor to the project.

Turnouts (Division Boxes)

Several turnouts (division boxes with small gates) were installed at the junctions of secondary and tertiary canals to regulate water flow. These structures played a crucial role in controlling water distribution across the farmland.

Figures 3 and 4 illustrate a division box similar to those constructed for the Adigudem irrigation project, helping to visualize their functionality and design.

Figure 3 Division box /turnout (FAO).

Stilling Basin

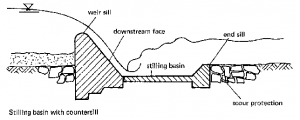

Two large drop structures were equipped with stilling basins, each with approximate dimensions of 3 m × 2 m × 0.4 m.

Figure 5 provides a typical example of a stilling basin, illustrating its design and functionality.

Figure 5 Typical Example of a stilling basin (www.nzdl.org).

Project Cost

The total cost of the project can be roughly estimated based on labor and supervision expenses. This includes costs for approximately 1,000 laborers, two tractor operators, two paid foremen, one engineer, one co-engineer, and a local community mobilizer. The construction period lasted approximately 10 months.

However, this estimation does not account for the costs of fuel, tractor maintenance, sand, cement, stone, and design or supervision fees.

Estimated Cost

Without including material expenses, the total cost is estimated to be over 3,500,000 Birr (at an exchange rate of 1 USD = 7 Birr), equivalent to approximately 500,000 USD.

Role of the Site Engineer

The site engineer played a critical role in the project, with responsibilities including:

- Translating the layout design from paper to ground using surveying instruments such as theodolite.

- Determining the placement of drop structures along the canals.

- Supervising and monitoring the construction process to ensure quality and alignment with the design.

Project Outcome

The project was completed and has enabled the local community in Adigudem to cultivate vegetables and crops throughout the year. The irrigation farm remains operational to this day. However, the reservoir’s capacity has significantly decreased due to silt accumulation, which has reduced the volume of water available for irrigation purposes.

Key Highlights

- Location: Adigudem, Tigray Region, Northern Ethiopia

- Construction Method: Solely manual labor (no canal-digging machinery was used)

- Irrigation Area: 136 hectares

- Earth Canals: Primary, secondary, and tertiary canals

- Drop Structures: 400 (approx. 1.7 m × 1.2 m × 0.3 m)

- Culverts: 3

- Turnouts (Division Boxes with Gates): Numerous

- Large Drop Structures with Stilling Basins: 2 (approx. size 3 m × 2 m × 0.4 m)